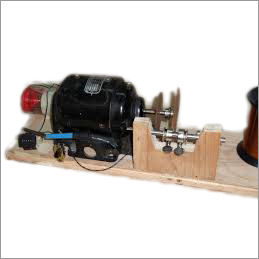

Coil Winding Machine

MOQ : 1 , , Unit

Coil Winding Machine Specification

- Maximum Coil Diameter

- 300 mm

- Body Material

- Mild Steel

- Noise Level

- Low

- Winding Speed

- 1200 RPM

- Display Type

- Digital

- Control Panel

- PLC Based

- Number of Heads

- Single

About Coil Winding Machine

As an acclaimed enterprise of the industry, we are engaged in supplying our clients Used Winder Machine. This machine is procured from trusted and reputed vendors of the market by our diligent agents. Offered machine is used for winding yarns in textile industry. We make available this machine for clients in different technical specifications as per their requirements. Also, we offer this Used Winder Machine at market leading prices to clients.

Features:

- Easy to use

- Optimum performance

- Longer working life

Advanced Control and Precision

Our coil winding machine is equipped with a PLC-based control panel and a digital display, ensuring precise operations. The automated system allows for consistent winding quality and straightforward adjustments during production, enhancing productivity and reducing manual errors.

Durability and Quiet Operation

Manufactured using mild steel, our machine ensures long-lasting durability and resistance to daily industrial wear. Its low noise level makes the work environment more comfortable, contributing to improved operator focus and workplace safety.

FAQs of Coil Winding Machine:

Q: How does the coil winding machine ensure accurate winding?

A: The machine features a PLC-based control panel paired with a digital display, allowing operators to set and monitor winding parameters precisely, resulting in consistent and high-quality coils.Q: What is the maximum coil diameter this machine can handle?

A: This coil winding machine can accommodate coils with diameters up to 300 mm, making it suitable for a wide range of industrial applications.Q: When should I consider using a single-head coil winding machine?

A: A single-head coil winding machine is ideal for applications requiring focused production, precise control, or where the operational process demands individual coil attention.Q: Where can I purchase or source this coil winding machine in India?

A: The machine is available through authorized importers, suppliers, and traders across India. Contact your local industrial equipment provider for availability.Q: What is the typical process for operating the coil winding machine?

A: Operation involves setting desired winding parameters on the digital display, securing the wire and coil, initiating the winding via the PLC panel, and monitoring progress until completion.Q: Can this machine be used for continuous production and what benefits does it offer?

A: Yes, its robust mild steel body and low noise feature make it suitable for continuous operation. Users benefit from reliable performance, reduced wear, and a quieter workspace.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS